Human surveillance for better asset management, identification and diagnosis of abnormalities and suboptimal operation are benefits attached to connecting sensors to assets and equipment. However, normal operation does not necessarily imply optimal operation. To obtain optimal production, an asset must be operated at appropriate set-points. For dynamic assets or systems, the optimum set-point changes with time. In such cases, the live data feed associated with the connected industrial devices can be harnessed to develop a dynamic set-point optimization mechanism.

What is a Digital Twin?

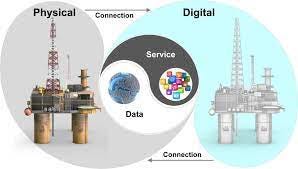

According to the Industrial Internet Consortium, a digital twin is a formal digital representation of some asset, process or system that captures attributes and behaviors of that entity suitable for communication, storage, interpretation or processing within a certain context. The digital twin of an entity is a means of, and is the single interface to, accessing its lifecycle information.

The digital twin information includes, but is not limited to, combinations of the following categories:

• Physics-based model and data,

• Analytical models and data,

• Time-series data and historians,

• Transactional data,

• Master data,

• Visual models and

- Computations.

Types of Digital Twin Systems

Discrete Digital Twin: A discrete digital twin is a single entity that provides value without needing to be broken down further. For example, the gearbox or motor for a ball mill in mining can be monitored and reported on at this entity level.

Composite Digital Twin: A composite digital twin is a combination of discrete digital twins that represent an entity comprising multiple individual components or parts. The composition may take place at different levels. For example, a production cell is a composite entity, whose digital twin consists of the digital twins of the devices within the production cell. An entire plant is a system, whose digital twin consists of several others composite digital twins.

Hierarchical Digital Twin: A set of component digital twins can be assembled into an equipment digital twin, a set of equipment digital twins can be assembled into a production line digital twin, and a set of production line digital twins can be assembled into a factory digital twin and so on.

Associational Digital Twin: There are associations between digital twins for example a oil pipeline digital twin is associated with its oil production and consumption equipment digital twins.

Peer-to-Peer Digital Twin: The peer-to-peer relationship is observed in a group of equipment of same or similar types, which perform the same or similar functions. The total effect of all the equipment is the simple sum of the effect produced by each piece of equipment. For example, in a wind farm, a group of wind turbine engines forming the composite digital twin of the wind turbine.

Benefits of a Digital Twin System

– Engineering Excellence: A digital twin serves as a proxy that collects data centrally for every entity and then makes that information available to different areas of the business for their specific applications through integration interfaces, such as Application Programming Interfaces (APIs). This improves decision-making through a shared understanding of operational status and reduces the overall lifecycle cost of operating and maintaining a plant.

– Product and Service Innovation: Digital twins can serve as the basis for advanced analytics and artificial intelligence applications to consume and enrich digital twin content. Alternatively, advanced analytics and AI applications can be part of a digital twin, making it an intelligent and self-contained entity.

– Manufacturing Efficiency: Digital twins can be used to develop high-fidelity soft-sensors or virtual sensors through physics-based models incorporated into the digital twin and serve as a proxy for the physical measurements.

- Service Optimization: Digital twins ease collaborative engineering through all lifecycle phases. This reduces the time spent on finding, exporting and importing information into tools required for any lifecycle task. Digital twins can resolve operational or maintenance issues that would otherwise result in expensive downtime. Digital twins can be made available to anyone, anyplace and at any time, sharing expertise around the world allows for 24/7 service and fast reaction time while maximizing expert use.

Digital Twin in Engineering Production

Production assets are dynamic entities that change their underlying operating conditions over time. Assets are subjected to discontinuities in behavior due to design changes, maintenance processes, re-stimulation and impact from nearby operations. If diligently performed, the time investment required to optimize set-points is approximately 10 days per asset per year.

The Digital twin is the solution to overcoming these challenges. The design and implementation of a digital twin for dynamic set-point optimization on an engineering production system using live IIOT data consists of several steps. These are:

1. Data processing: Collection, profiling, clean-up, transformation and cloud-database maintenance

2. Simulation: Automated cloud-database triggered field data relevant simulation

3. Inverse modeling:

a. Connecting real-world IIOT data with simulations to learn system unknowns

b. Evaluation: Estimate how closely the digital twin mimics the real-world asset from history

c. Calibration: Implement initial steps using insights from digital twin to account for uncertainty

4. AI Model Recommendation: Deploy automated recommendations for set-point adjustments with updates based on dynamic trending of the asset.

However, the key to maximize investments in digital twin deployments is to start thinking from the value perspective. This is why a digital twin strategy is a first step getting started. A digital twin strategy provides a more promising path to effectively manage information, circumvent productivity bottlenecks, and foster enterprise-wide collaboration, increase market agility, and drive business value in the digital age.

A digital twin strategy sets an organization up for long-term success; however, the first challenge is identifying a starting point.

The steps below may be considered in a digital twin strategy:

1. Define all potential digital thread use cases across the enterprise.

2. Prioritize the digital thread use cases that will drive the most business value.

3. Conduct an internal digital audit to identify relevant data.

4. Demonstrate quick digital thread wins and scale to drive enterprise-wide transformation:

The digital twin opportunity is immense to capture value across engineering production today and drive transformative change in the near future.